GPS Navigation with Automatic Control

An automated system for precise guidance of agricultural vehicles.

Service provided in partnership with AgroOSA

- GPS accuracy of +/- 2.5 cm with RTK base.

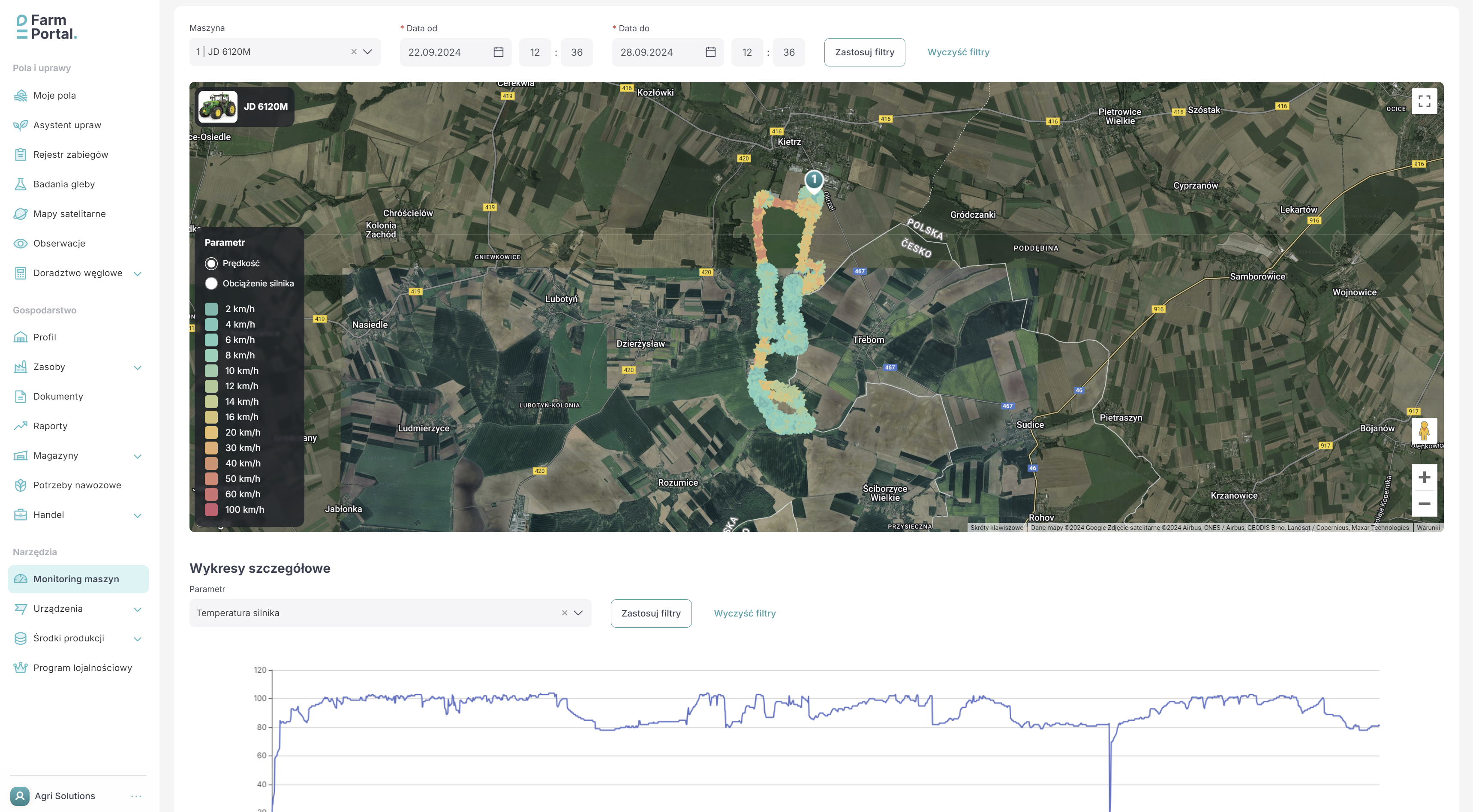

- Travel routes and reports within the FarmPortal application.

- Installation across Poland with training provided.

- User-friendly software in Polish.

- Over 500 installations.

- Easy transfer between vehicles.

Get up to PLN 200,000 in funding under

- Agriculture 4.0, or

- Investments Contributing to Environmental Protection

Basic agroOSA System Features

Control Systems

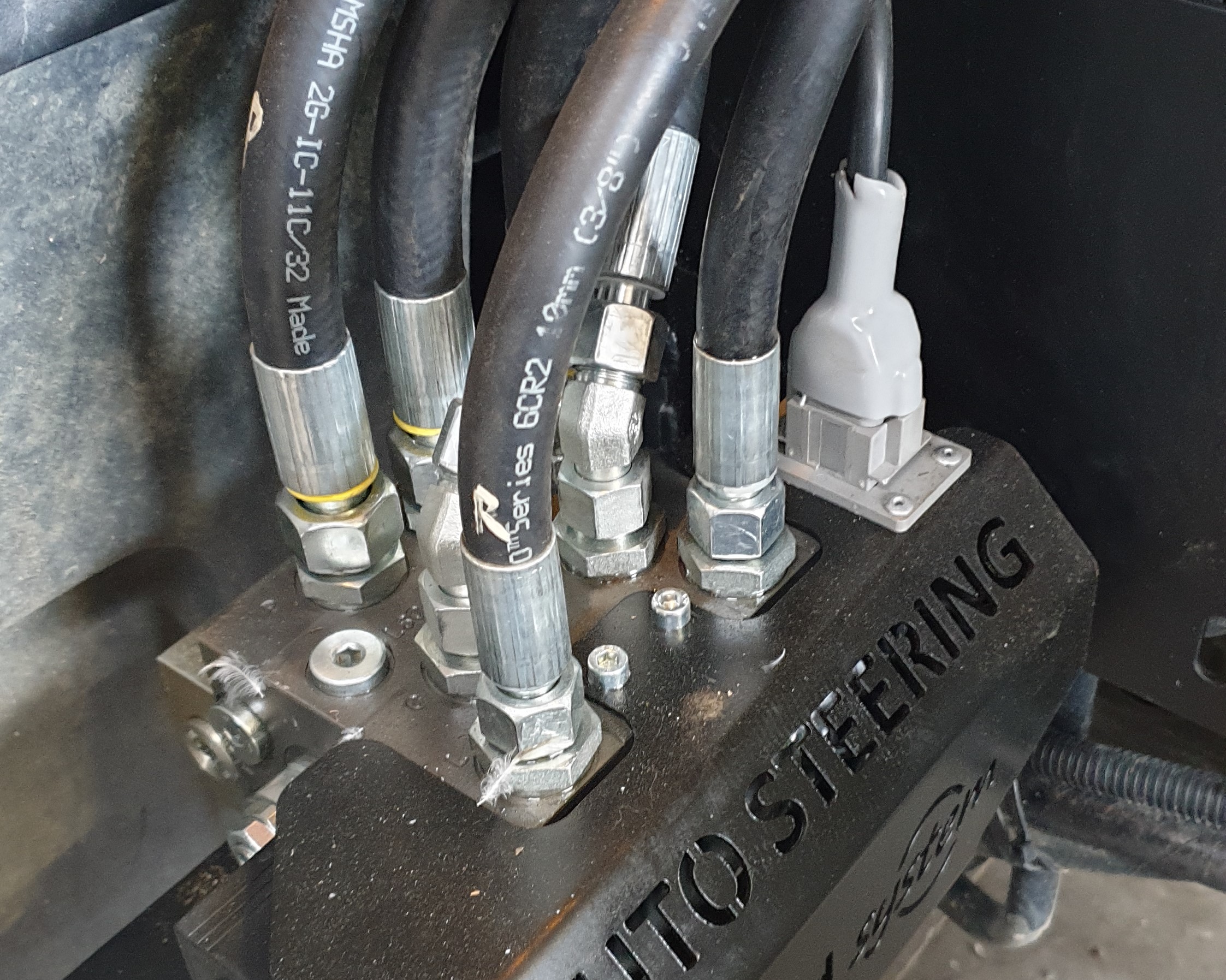

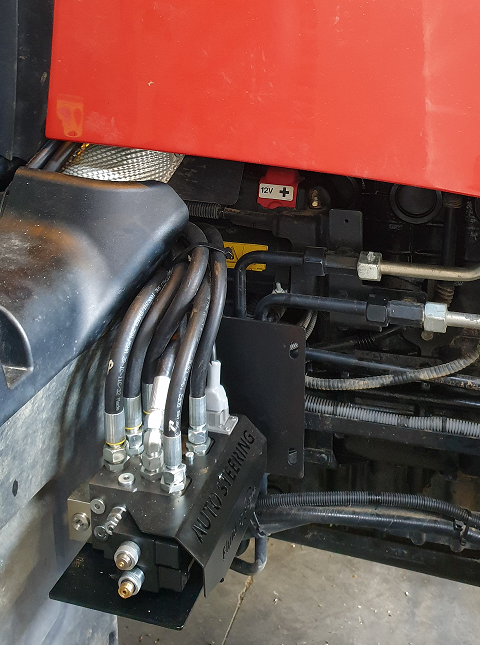

Automatic Vehicle Control

A hydraulic valve mounted in the tractor ensures precise guidance in the direction set by the operator in the navigation application – full functionality at low speeds (from 0.05 km/h).

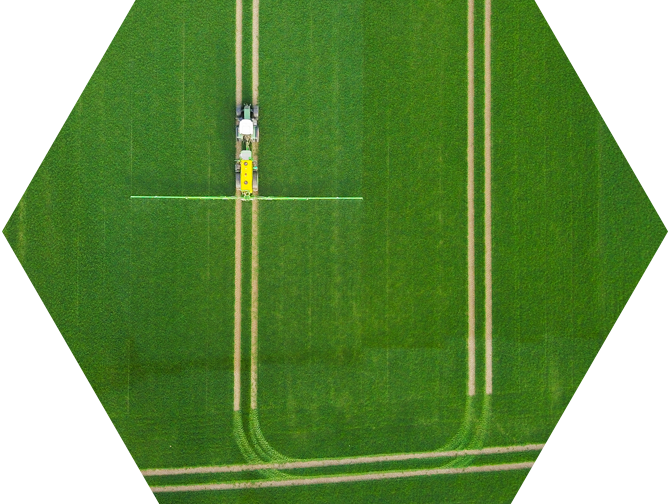

Thanks to online RTK signal correction, the system maintains route repeatability within +/- 2 cm (year to year, day to day) during field operations.

Automatic U-Turn

Integration of advanced precision agriculture algorithms into the navigation software enables automatic turning of the tractor – the operator can set the direction, choose the turning path, and designate technological paths while considering the appropriate width of working tools. Minimizing overlaps and gaps significantly saves fuel and materials, increasing field work pace and productivity.

Recording Operations and Control via the Application

Simple and intuitive software in Polish allows you to add fields, working machines with their settings, record and replay tractor operation parameters, and resume interrupted tasks with tool editing. The software continuously transmits current information on ongoing operations, their progress and efficiency, travel direction, technological paths, and other useful parameters.

Tool Control

Control of working tool sections is now possible – we offer solutions that allow control of up to 16 analog sections, with development underway to implement ISOBUS communication.

24/7 System Monitoring

System monitoring ensures rapid detection and resolution of faults or device replacement in case of failure.

Have Questions?

Contact Us

Tomasz Rupacki

Business Development Manager

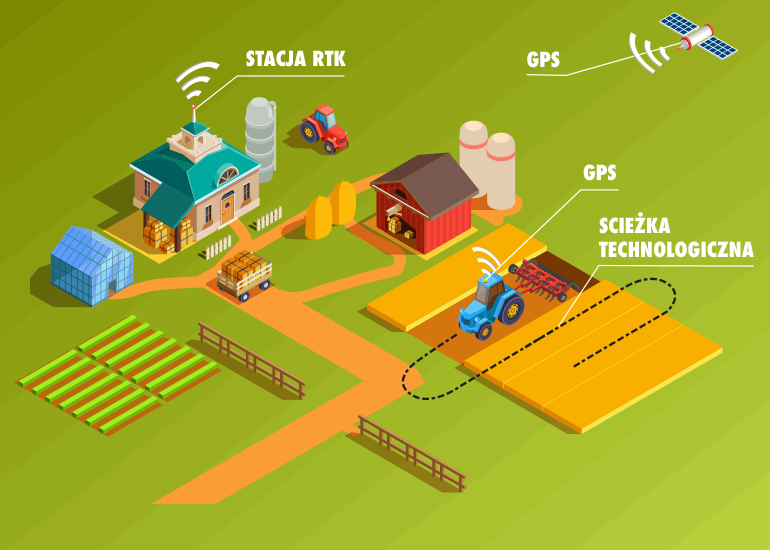

Principle of agroOSA System Operation

RTK Station

RTK (Real Time Kinematic) transmits correction data from the station to the receiver (vehicle). Route determination is performed with precision up to +/- 2 cm. The maximum distance to the RTK base is 30–40 km.

GPS Receiver

Receives the GPS signal and RTK corrections to determine the optimal route and transmits the position to the vehicle control system.

Technological Path

Automatically plotted route with appropriate distances and widths for the machine and tools.

The system consists of 4 main components

Capabilities of GPS guidance with auto-steering

- Field mapping, area measurement, indication of coverage in % or ha subjected to agronomic treatment, and elimination of overlaps and gaps during operations

- Electric control of working tool sections (1–16 sections) to avoid overlaps

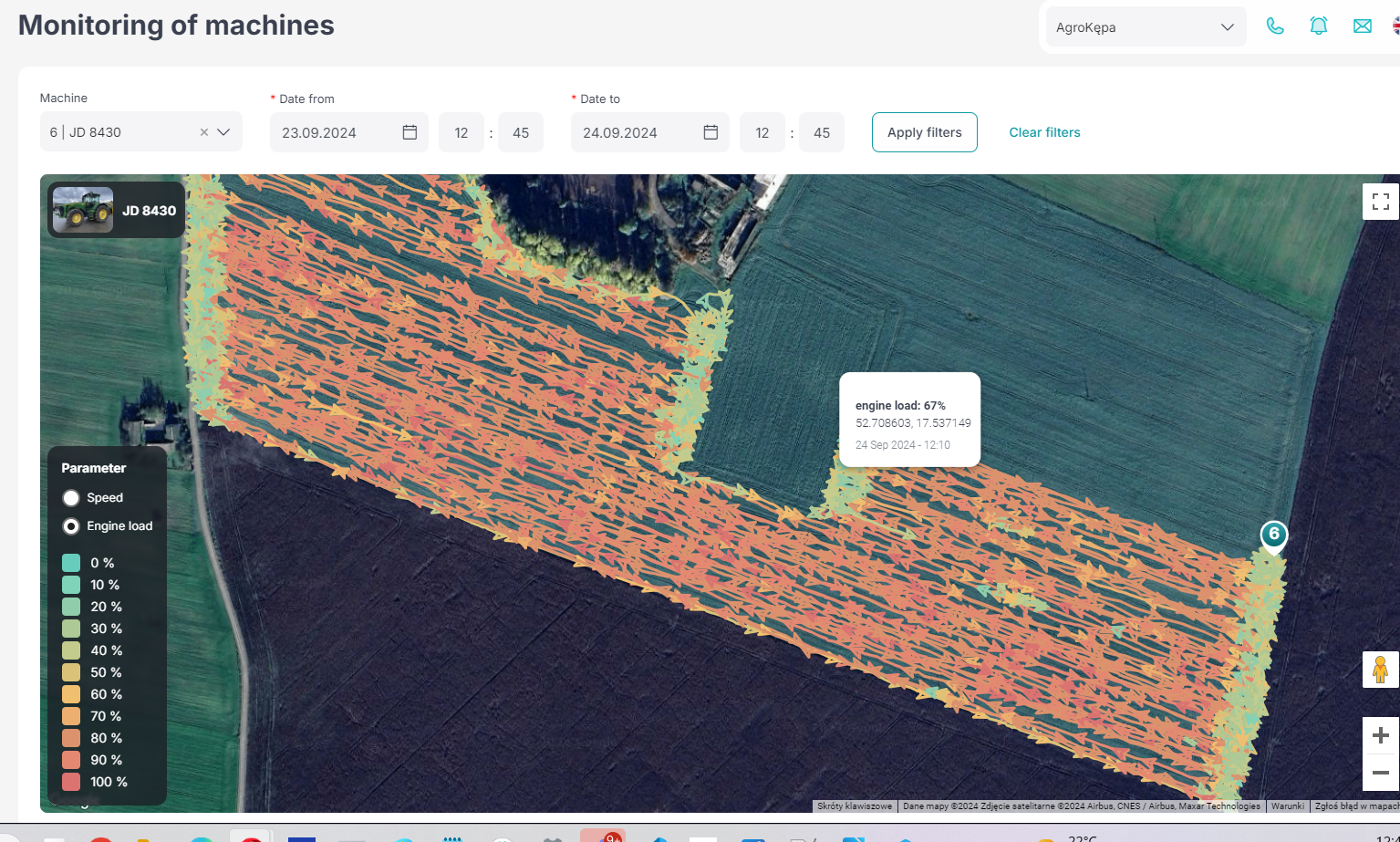

- Monitoring of machine position and operation

- Archiving of completed operations with dates in the FarmCloud application

- Resuming interrupted work – continuation of agronomic treatment

- Real-time calculation of efficiency in ha/h during operation

- Adding straight lines AB on the aerial/satellite map as well as curved lines AB to determine the tractor's guiding line

- Virtual cross-track mode with audible warnings when deviating or crossing the deviation line

- Guiding the vehicle along the designated line with precision up to +/- 2 cm for electric steering or hydraulic modules

- Reading CAN data from tractors and other agricultural machines

- Monitoring actual fuel consumption, total mileage, engine temperature, and other parameters

- RTK base with power supply

- Power supply: 10–30 V